Enhancing Industrial Operations with Tailored Storage Solutions

We are excited to share a compelling use case that illustrates how our tailored storage solutions revolutionize industrial operations. Through collaboration, innovation, and a customer-centric approach, we empower businesses to achieve unparalleled efficiency and safety in their storage processes.

Scenario:

Customer Challenge: A prominent industrial client in Collie, WA, faces the challenge of storing emulsifier fuel blends safely and efficiently. Their existing storage setup lacks the necessary containment measures, posing risks to both the environment and their operations.

Solution Exploration:

- Customer Engagement: The customer reaches out to us, seeking a solution to their storage challenges. Our expert team promptly engages with them to understand their specific requirements and operational constraints.

- Customization Proposal: Leveraging our extensive expertise in storage solutions, we propose two tailored designs:

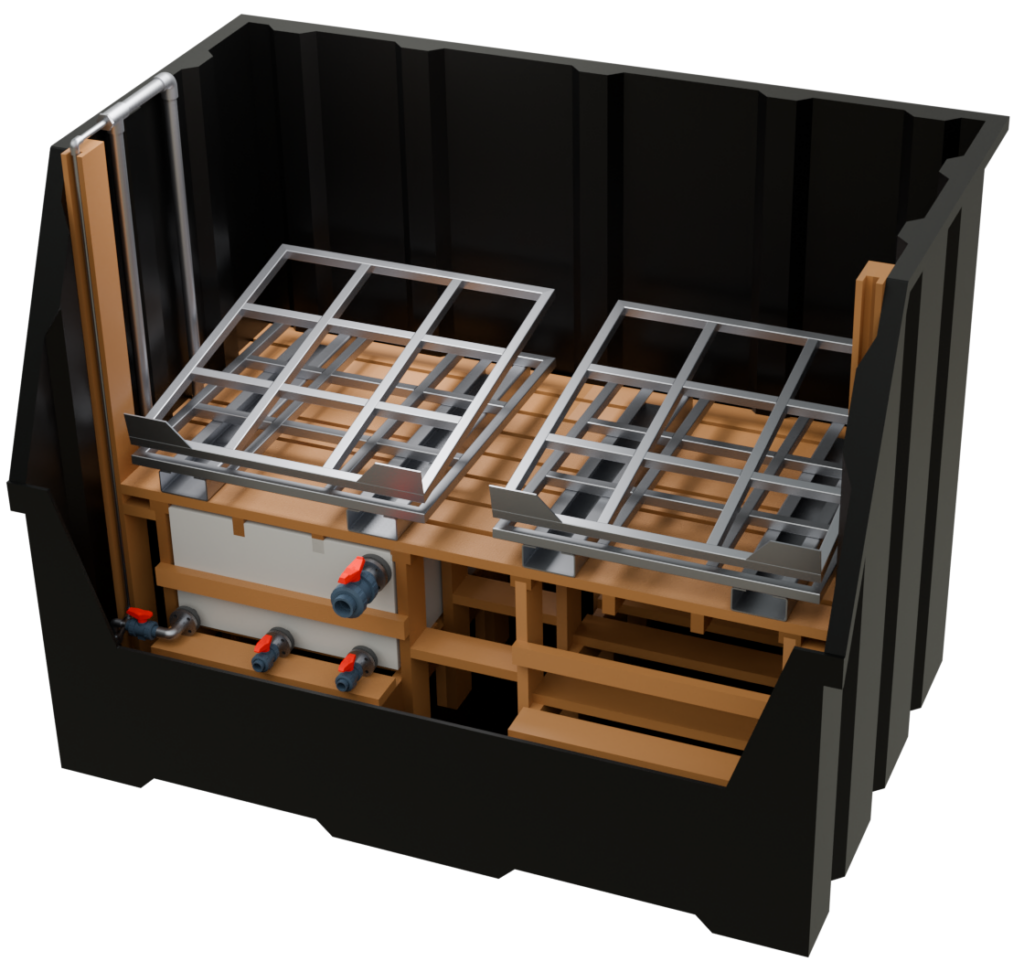

- Design 1: Incorporates a single day tank within a double bund, ensuring precise fit and optimal containment for emulsifier fuel blends.

- Design 2: Offers flexibility by omitting the day tank while maintaining the integrity and efficiency of the storage solution.

- Innovation Integration: To address site-specific challenges, such as compatibility with existing infrastructure, our engineering team incorporates innovative features. This includes replacing the front rotomoulded wall with a 15mm HDPE sheet for enhanced durability and compatibility.

- Material Selection: We prioritize quality and longevity by selecting high-grade stainless steel for critical components, guaranteeing durability and longevity in the demanding industrial environment.

Customer Partnership:

- Presentation and Collaboration: We present both design proposals to the customer, providing detailed explanations of features, benefits, and compatibility. Through collaborative discussions, we ensure alignment with their operational needs and preferences.

- Approval and Implementation: Following thorough review and deliberation, the customer selects their preferred design. With their approval, we proceed with manufacturing and delivery, adhering to strict quality standards and timelines.

Success and Impact:

- Installation and Deployment: Our custom double bund solution is successfully installed at the customer’s site in Collie, WA. The seamless integration and precise engineering enhance fuel storage efficiency, mitigating risks and ensuring compliance with regulatory standards.

- Operational Transformation: With our tailored storage solution in place, the customer experiences a transformative impact on their operations. Enhanced safety, efficiency, and peace of mind enable them to focus on driving growth and innovation in their core business areas.

Conclusion:

Through proactive engagement, innovative design, and unwavering commitment to customer satisfaction, Transtainer delivers more than just storage solutions—we deliver peace of mind and operational excellence. This use case exemplifies our dedication to empowering businesses to thrive in dynamic industrial environments.

Contact Us Today:

Ready to elevate your storage capabilities and transform your operations? Contact Transtainer today to explore how our tailored solutions can drive success for your business. Let’s embark on this journey together, towards a safer, more efficient future.